As COVID-19 hotspots have spiked— and continue to spike—throughout the country, Mason & Hanger is leaning on 3D laser scanning technology to keep teams and customer safe. Government projects that support the U.S. National Security Mission do not stop in the face of COVID and Mason & Hanger has used innovation to maintain the momentum of its design projects over the past few months. In utilizing their scanning technology to create 3D photo realistic models along with typical point clouds for customers, their quick response to the immediate situation has kept projects alive and moving amidst safety and travel restrictions.

In recent months, when travel for both the firm and partners was not possible, Mason & Hanger utilized a team of two to provide 3D laser scanning to survey a design/build proposal for a military training housing barracks in a COVID hotspot in New Jersey. Their innovative approach helped avoid numerous teams from having to travel to the location, keeping the project team and A/E and construction teams safe. In a 2-day period, Mason & Hanger took nearly 300 location scans with three scanners running, and stitched them together like a puzzle to establish an interactive and accurate 3D virtual model of the entire building. “Our government customers are pleased with the results, in fact they were pleasantly surprised by what was included in the virtual models,” stated Mark Mates, Mason & Hanger’s Manager of Design Technology, who led the scanning project and traveled to the site. “This helps avoid sending extra people with a notepad and a tape measure on site, particularly at a challenging time like now when travel isn’t possible or safe,” Mates added.

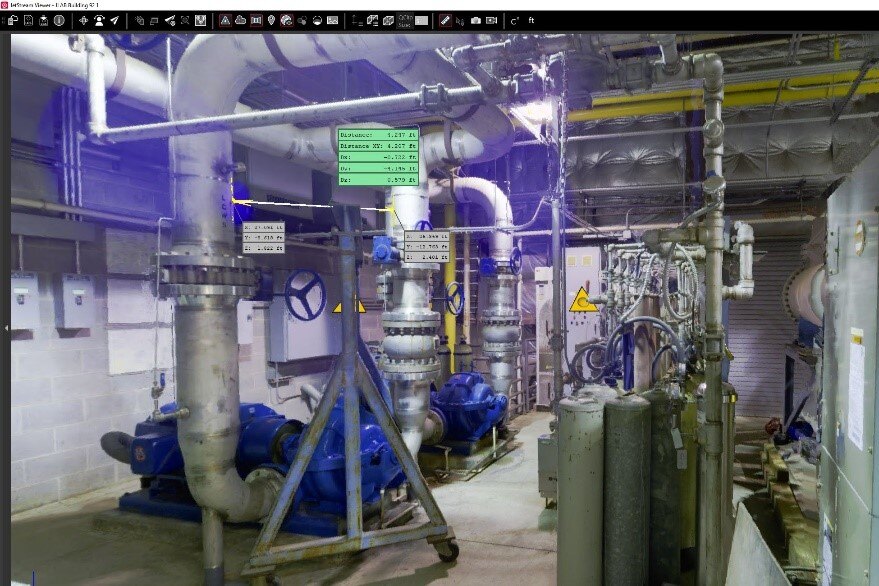

Mason & Hanger has been using 3D technology in house to bring added time and travel efficiencies, and in this case, eliminate travel for entire teams during a full scale pandemic, which protects the teams and partners —with added financial savings, including longer term cost savings that may ultimately be reflected in overall contract pricing. The 3D models allow any project stakeholder or prospective bidder to digitally navigate a building or site as the next best thing to actually visiting the site. Stakeholders can use free-viewing software to walk through and navigate models while also taking measurements, when needed.

“I believe this is an approach that will get us past the COVID-19 pandemic and will become a method of operating moving forward,” stated Jon Miller, Director of Operations, Mason & Hanger. “As we continue to move toward a more virtual world, this is an application that will become more prevalent as more cost and time savings are realized,” Miller concluded.

Additional Benefits

With some of the more remote locations, both travel and facility clearances for larger survey groups can consume a lot of time, particularly if there is a need to return to a location multiple times to explore new aspects or items missed. While site visits are still important, they can be limited to a few hours initially [pre-award]. Instead, the 3D laser scan provides a limitless “re-entry” for the team needing to go back and explore the building or site’s intricacies and measurements after the initial visit during the design process. Another benefit to the technology is that it helps teams reach the “harder or less appealing areas” of a facility or location. In example, going into a crawlspace, attic, armory, or the areas of a government site requiring higher levels of clearance can be problematic or altogether avoided by the majority of the project team.

In summary, Mates agrees that beyond the COVID pandemic, this is the new standard for the A/E industry, “Not only is the use of 3D laser scanning technology the safest method for site visitations, minimizing travel and person-to-person contact of what has traditionally required larger survey teams, the end result is a more efficient use of time, travel, and cost. It is also bringing greater overall accessibility to the finer details ultimately providing the best designs and solutions for the customer.

We are certainly communicating this to all of our contractors to help them understand the style in which we work, to be more collaborative. We think this should be a standard in the scope of work, no matter what.”