Our professionals provide the expertise required to design the electrical and technology systems for many different types of facilities located throughout the world. In addition to the capabilities required for most projects, our engineers are also skilled in designing and specifying the redundant, uninterruptible, and off-grid power systems that are typical of the many mission-critical facilities we design.

Our electrical teams work to identify the best, cost-effective, and sustainable solutions for your project, including power generation, and or renewable energy options. In the process of selecting and configuring your system, we use a value engineering approach with consideration not only of the initial cost, but also the ease of maintenance and future operating costs of your project.

We have a cleared staff of professionals that includes licensed Professional Engineers (PE), NCQLP Lighting Consultants (LC), and USGBC LEED Accredited Professionals (LEED AP BD&C).

Our practice is not limited to low voltage applications but also includes medium voltage power distribution and transformation up to 35kV classifications. Our expertise in power system analysis includes load flow, fault current, time-current coordination, and arc flash studies.

We focus on sustainable design and utilize energy efficient LED lights and lighting control systems, including dimming, daylighting, and occupancy and vacancy sensors to ensure that the minimum amount of energy is used to provide the required illumination for each type of area. The vast majority of our projects exceed ASHRAE 90.1 energy requirements.

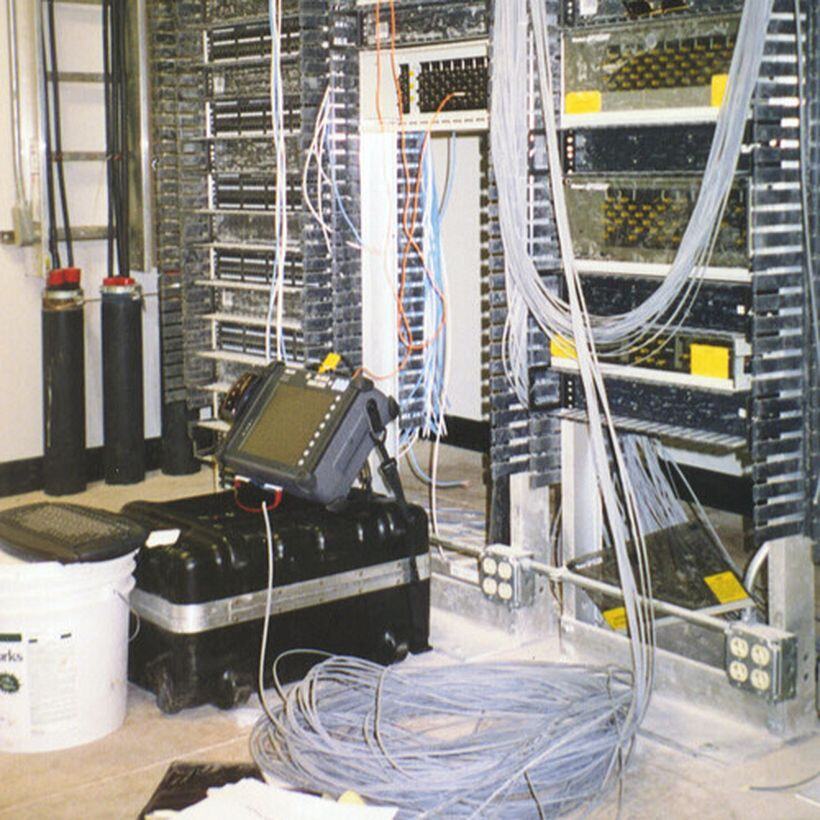

Low voltage applications are handled by our specialists in the Technology System Group. Our cleared staff of Registered Communications Distribution Designers (RCDD), Outside Plant experts (OSP), Electronic Safety and Security specialists (ESS), and Certified Technology Specialists (CTS) design sophisticated electronic security systems, attractive audio/video systems, structured cabling systems, and telecommunication equipment rooms for a diverse set of clients with a wide range of needs.

These designs incorporate classified as well as unclassified requirements for domestic and international locations. The results of which are unique for each project.

Mason and Hanger is committed to the success of your project, no matter how large or small. We understand that our clients have the heavy burden of keeping Americans safe all over the world, and when we are trusted to design the electrical and technology systems for your projects, we take that responsibility very seriously.

We are well versed in the design criteria used by our clients, and in some cases have helped develop that criteria. However, we can also think outside the box and are always looking for new technologies and better solutions to serve the needs of your projects. We don’t fear change and readily overcome challenges with schedule and provide value engineered solutions to reduce costs.

We have vast experience doing both design-bid-build and design-build projects. This experience helps us provide the best, cost-effective, and sustainable designs to meet our client’s and their client’s needs.

"I just returned from Dubai and I wanted to share with you some of the things I saw and some of the information that was relayed to me. The jobsite looked phenomenal. The installation was the best that I have seen. I had several people with OBO come to me to praise the design and installation on the project. Mike Razook (OBO TSS), Mahfuzar (OBO Electrical), and Gordon (OBO on site Electrical) all said it was the best project they had ever seen. Mike said there isn't another project even close to as good as Dubai. This was by far the smoothest project that I have worked on. Thanks to you and your team at Mason & Hanger for helping make Dubai a highly successful project."

- Joshua H. Durr, Electrical Engineer

Mason & Hanger provided electrical engineering design services for a new two-story, 51,667 SF mechanical, electrical and plumbing plant addition to replace the existing central plant. The IRS Enterprise Computing Center operates 24 hours a day, 7 days a week, 365 days a year. The project included phased replacement of the majority of the existing electrical plant equipment without interruptions or significant reductions to existing operations. Existing electrical equipment was assessed and the expected operational life determined so existing equipment could be re-used to the greatest extent practical.

Electrical design included a new static uninterruptible power supply (UPS) system to replace the existing rotary UPS system. The configuration of the new system includes four groups of UPS, each group consisting of four modules at 750 kVA each. A parallel configuration for each UPS group provides N+1 redundancy. This system is sized to support a load density of 50 watts/SF. The design also employs the use of static switches to serve existing PDUs from dual UPS sources.

The new system offers a high level of energy efficiency resulting in a significant reduction in annual operating costs. The project also incorporates GSA design standards for secure facilities and sustainable design criteria.

Mason & Hanger provided electrical engineering design services for the new $125M, 57,620 SF, cogeneration central utility plant that provides electricity, steam, hot water, and chilled water with thermal storage to office buildings, parking decks, labs and vivaria — 20 buildings totaling 3,900,000 SF.

The plant provides 29MW of electricity, 12,000 tons of cooling provided by centrifugal chillers, 120 MMBtu/hour of hot water provided by turbine heat recovery, and up to 35,700 pph of process steam. High pressure steam from turbine heat recovery provides power generation for a 5MW steam turbine. The design of the cogeneration power plant included the integration to connect with the local utility company power grid at 69kV.

The electrical design included two 7.5 MW turbine-generators, one 4.5 MW turbine-generator, one 4.7 MW steam turbine-generator, and two 2.25 MW diesel black-start generators. All process equipment is controlled through a plant control system that integrates all programmable logic controllers from each piece of equipment to a central control room.

Mason & Hanger designed the electrical systems for the Central campus job including primary power distribution (underground 13.2 kV service), uninterruptible power supply, emergency power, site lighting (parking lots, walkways and building exterior), building power and lighting systems, and public address system.